“Yangquan is one of the largest coal producers in China. The R-GAS™ gasification process offers a step-change improvement in efficiency and cost over current gasification technology and is uniquely capable of gasifying China’s low-rank coal.

Mr. Zhai Hong, Chairman of Yangquan Group

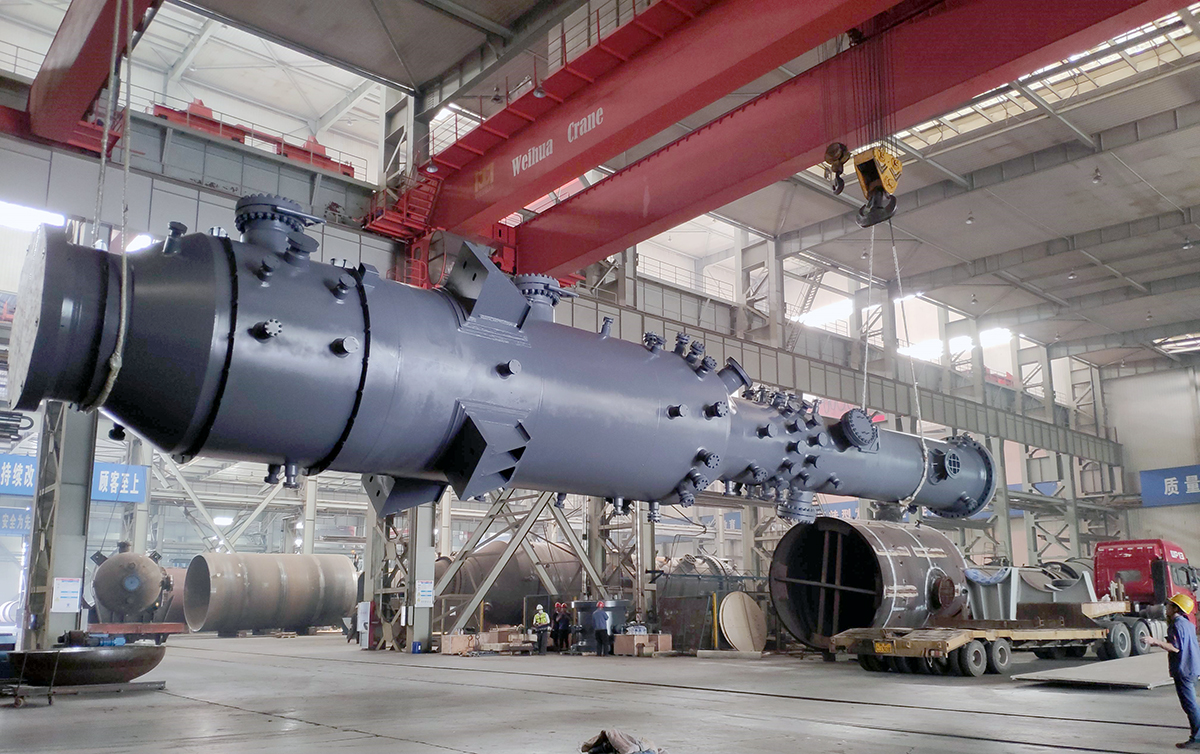

GTI’s innovative R-GAS™ process is being demonstrated with Global Fortune 500 company Yangquan Group at one the largest chemical plants in Shanxi Province, China.

In 2019, construction was completed, and commissioning is underway on the facility that will showcase breakthrough gasification technology to lower costs and minimize environmental impacts. The project is now in Phase 2, which will continue until 8,000 hours of cumulative operation have been successfully achieved.

The project follows up successful long-duration testing of high ash-fusion temperature feedstocks using GTI’s R-GAS gasifier technology at our pilot-scale facility in Des Plaines, IL. The R-GAS™ technology has been successfully operated at pilot-scale (18 tons per day) on a diverse range of carbonaceous feedstocks—all with excellent test results.

The innovative technology can gasify the types of feedstocks predominant in China, which conventional gasification technologies have to date been unable to gasify due to its challenging properties. Testing validated the robustness of the R-GAS process, demonstrating the capability to achieve >99% carbon conversion even with this low-rank feedstock.

The gasifier footprint is about one-tenth the size of competing entrained flow technologies, and the compact size and advanced design features drive higher efficiency and lower cost. R-GAS consumes up to 30% less water and the higher efficiency results in lower overall emissions. The design enables rapid start-up and shut-down, feedstock flexibility—able to operate with a diverse range of carbonaceous feedstocks—and process optimization capability. It can be used for liquid fuels and chemicals production, as well as power generation.

Capital expenditure is estimated to be 15–25% lower than the most economical entrained flow technology. The Yangquan industrial demonstration will validate long-duration reliability, operability, and capital costs.

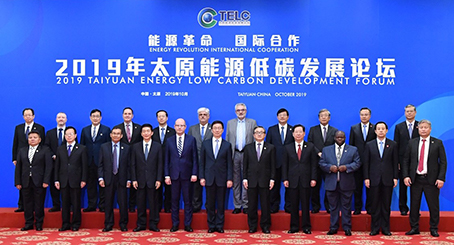

In support of this effort, GTI President and CEO, David Carroll and Michael Rutkowski, Senior Vice President, Research and Technology Development met with China Vice Premier Han Zheng and Shanxi Provincial government Vice Governor Wang Yixin and presented to energy ministers from around the world at the Taiyuan Energy Low Carbon (TELC) Development Forum in 2019.

Find out more about the R-GAS Gasification Technology. (2.7MB pdf)

Learn More

Contact the energy experts today